Electrolyzer Technology

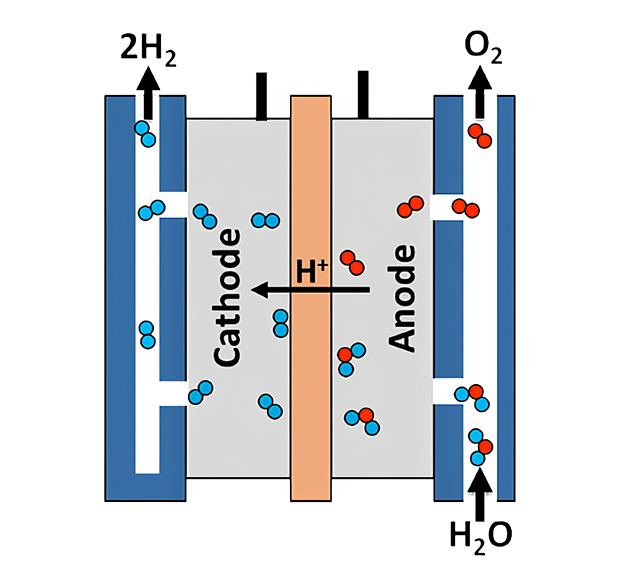

In hydrogen electrolysis, the PEM allows protons (hydrogen ions) to flow from an anode, where water is oxidized to produce oxygen and hydrogen ions, to a cathode, where the hydrogen ions combine with electrons supplied by an electrical power source to form hydrogen gas.

The hydrogen gas is collected and stored for use as a clean fuel. The fuel cell performs the reverse process, using hydrogen and oxygen to create electricity.

In CO2 electrolysis, carbon dioxide is converted into valuable products like carbon monoxide, hydrocarbons, or alcohols. These processes are utilized in energy storage, transportation, sustainable fuel production, and chemical manufacturing..

The PEM allows the passage of protons (hydrogen ions) between the electrolyzer’s or fuel cell’s anode and cathode. It is a single, thin membrane, that allows protons to pass and helps manage water within the cell. Water keeps the PEM hydrated, which is crucial for proton conductivity.

Frequently Used Terms:

Green Carbon: Involves natural carbon sequestration processes in forests/plants, wetlands, and agricultural ecosystems, helping to mitigate CO2 levels and promote environmental health.

Grey Carbon: Involves carbon emissions from human activities, contributing to increased atmospheric CO2 levels and exacerbating climate change.

Green Hydrogen: Hydrogen produced using renewable energy through electrolysis, resulting in zero CO2 emissions and promoting sustainability.

Grey Hydrogen: Hydrogen produced from natural gas through steam methane reforming, emitting significant CO2 and relying on fossil fuels.

Experienced Proton Exchange Membrane (PEM) Frame Injection Molder

We have over 20 years of expertise and experience in manufacturing PEM frames. That expertise allows us to make PEM frames with:

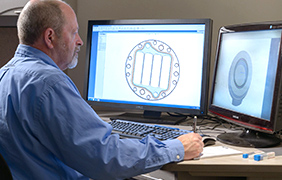

Customization and Flexibility – We use high performance thermoplastics on which our engineers and technicians have extensive knowledge to ensure strong, long-life frames. Our team can manufacture any shape from small circular frames to large rectangular frames.

In addition, we can produce complex designs to produce intricate flow channels necessary for optimal performance. The channels create a torturous path for water to travel through and break down into its component parts, hydrogen and oxygen.

Cost-effective Manufacturing – Our team consults with our clients to help them specify a material whose characteristics comply with their PEM frame requirements. The team also will recommend process improvements and mold modifications to optimize the PEM frame injection molding process.

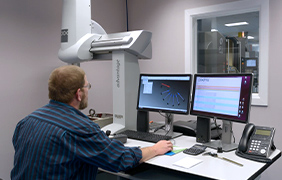

Robust Quality Control – Our independent quality department ensures that the client’s PEM frame injection molding process is thoroughly documented and makes repeatable parts to client specifications. We use Advanced Product Quality Planning (APQP) to establish PEM frame quality control throughout the appropriate manufacturing process steps. Our Production Part Approval Process (PPAP) prepares our manufacturing team to produce PEM frames that meet and exceed client requirements.

Full traceability – Our state-of-the-art metrology lab calibrates its measurement equipment with calibration equipment whose own calibration is traceable to national standards maintained at the National Institute of Standards and Technology (NIST). Our highly accurate measurement tools ensure our clients receive frames that meet all their requirements.

With our expertise, experience, quality systems, and measurement tools in this unique precise technology, we can manufacture high performance, high quality PEM frames for the first order and every order.

Get In Touch

Join us in the pursuit of sustainable injection molding solutions for alternative energies. Contact TechNH today to discuss your project requirements and discover how our expertise PEM frames injection molding can help your company lead the field in this growing industry.

With TechNH as your partner, you can achieve your goals without compromising on quality or innovation.