TechNH specializes in manufacturing a wide range of components for the medical market, from large housings to tiny couplings.

Some of the medical applications we have provided parts for include:

Lab Equipment

We produce high-quality components that meet the rigorous standards of laboratory environments.

Patient Monitoring

Our precision-engineered parts play a crucial role in patient monitoring devices, ensuring accuracy and reliability in healthcare settings.

Surgical Components and Devices

We manufacture intricate surgical components and devices with precision and attention to detail, supporting medical professionals in their work.

Orthopedic Components

TechNH produces orthopedic components with precision and consistency, contributing to improved patient outcomes in orthopedic surgery.

Blood Handling

Our expertise extends to components used in blood handling equipment, ensuring safe and reliable performance in critical medical procedures.

Why Clients Choose Us

When you partner with TechNH for your medical plastic injection molding needs, you benefit from:

TechNH is fully compliant with ISO 13485:2016 requirements, FDA registered, and complies with 21 CFR 820 regulations. Each component we produce meets or exceeds regulatory requirements and medical industry standards, guaranteeing reliability and safety.

Our expertise extends across various molding resins, including polycarbonate and LCP (Liquid Crystal Polymer), ensuring that we can meet the diverse needs of our clients. Whether you require components with specific material properties or custom solutions, our team has the knowledge and capability to deliver.

Beyond manufacturing, we offer comprehensive assembly and packaging services to provide turnkey solutions for medical applications. Whether you need precision-engineered components or fully assembled products, TechNH is your trusted partner. We ensure that every aspect of your project, from design to delivery, meets our stringent quality, reliability, and compliance standards.

From initial design to production and beyond, TechNH provides comprehensive support throughout every stage of your project. All our clients are assigned a primary contact point, a dedicated customer service representative, and project manager (a degreed engineer). We are committed to delivering a seamless experience, offering guidance and expertise to ensure our success, together.

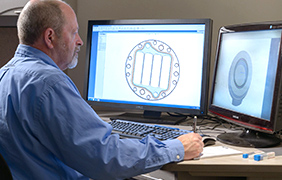

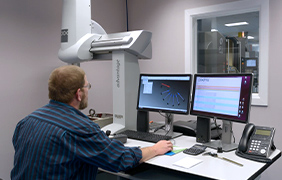

Our team of seasoned engineers utilizes cutting-edge technologies and techniques to deliver precise solutions tailored to your unique needs. With our focus on precision, you can trust that your project will be executed with meticulous attention to detail and accuracy.

Frequently Asked Questions

Medical injection molding is a specialized form of plastic injection molding used to produce components and products that comply with the requirements of the medical industry. Parts must be manufactured using biocompatible, medical-grade materials to ensure safe and reliable products that are compliant with Food and Drug Administration standards or ISO 13485, quality management for medical devices. Many medical components such as syringes and catheters require extremely tight tolerances. Requirements for contaminant-free components can necessitate production in a cleanroom environment. Manufacturers must have procedures for ensuring traceability of medical part production.

PVC injection molding describes the use of polyvinyl chloride (PVC) to produce plastic parts. PVC is a durable, chemically resistant plastic that can be modified to have a range of hardness levels. Examples of rigid PVC use include pipes and other construction products. Flexible PVC comprises such products as soft tubing, gaskets and intravenous fluid bags.

Biocompatible materials safely contact living tissue and biological systems without creating an adverse reaction. The materials must not cause toxicity, an immune response or any type of irritation when used for medical applications. Examples of biocompatible plastics are polyethylene, polypropylene, polycarbonate and polyvinyl chloride. These and other biocompatible plastics withstand the various methods of sterilization. They are also resistant to bodily fluids, drugs and other chemicals that the plastics may encounter in a medical application.

The factors that contribute to the cost of an injection mold include the material selected, the complexity of the part and the number of cavities for multiple part molds. Aluminum molds, typically used for prototype or low-volume production, can cost between $5,000 to greater than $30,000 depending on the size and complexity of the mold requirement. Steel molds, used for high-volume production, can range in price from $15,000 for a simple design to over $100,000 for high-complexity designs. Steel molds trade off high cost with the benefits of high durability and a much longer lifespan.